Don't Let Shipping Damage Stress You Out

Pelican is the world leader in protective case solutions, earned over a 30 year long journey. Along the way we perfected injection molding, roto-molding and robotic assembly processes to deliver high quality cases consistently. The outcome is our Advanced Case Solution™, your guarantee that every aspect of protecting your medical device is built right in.

Case Manufacturing

We supplement our primary case manufacturing plants with 8 regional facilities known as Advanced Case Centers, where many of our customizationservices are available. This allows many of our customers to be directly involved in the design and testing of first article samples.

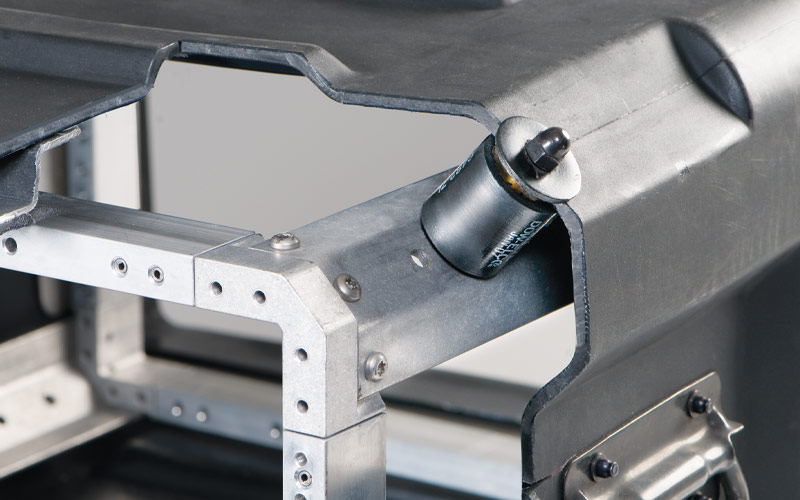

Metal and Foam Protection

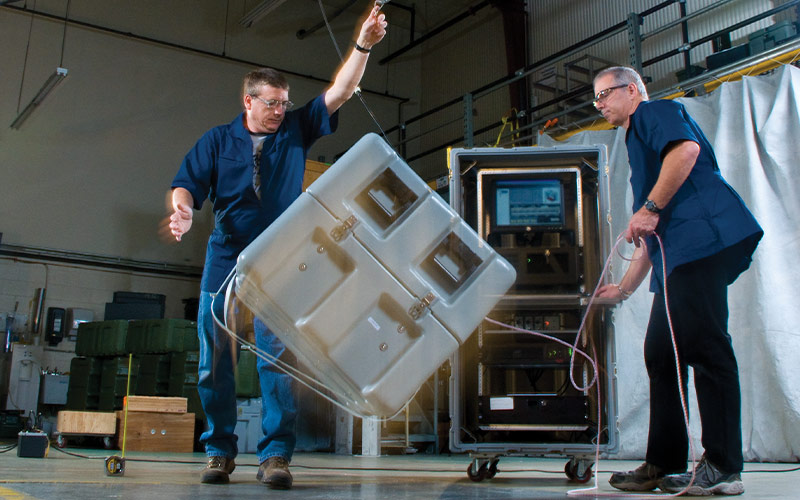

To protect this equipment from impact forces we use elastomeric shock mounts to isolate the metal fixture from the case shell. Shock absorbing foam is available in a variety of densities, which is determined based on the fragility and weight of your equipment. Medical specific foams are compatible with radiation or bleach sterilization, and anti-bacterial foam can block mold and mildew.

Electronic Interface

Our cases are the ultimate mobile protection solution for electronic OEM solutions. Installing your controls in a Pelican™ case enables its use in any environment, and closing the lid is all it takes to prepare for shipment. Water proof panel frames provide a secure ledge just below the opening line for mounting an electronics dashboard. CAD files are available in most case sizes for rapid engineering. Various bulkhead connectors allow electronic connection even with the lid closed.

A great medical device is only great when it arrives in working condition - our job is to remove that uncertainty.

Know what you’re getting into by choosing a Advanced Case Solution™ from Pelican.

The Anatomy of an Advanced Case Solution

A

B

C

D

E

F

K

G

H

I

J

Solutions Delivered

Over 30 years of extreme applications have forged our technical expertise

Communication + Collaboration

Pelican's integrated process flow anticipates your unique protective packaging requirement. Work with our engineers to create the most effective protection for your equipment. Trust our 4 stage engineering process to eliminate logistical risks through evaluation, design and engineering, prototyping and testing, and manufacturing.